In recent years, the market of plastic pipe is developing steadily in China. PE,PPR and UPVC pipe play an important role. Wherein the development of PE pipe is most remarkable.PE pipe has a wide range of application. Wherein the water supply and gas pipe is one of the largest application market.

Our company receive good reputation because of the reliable quility and reasonable price. We have rich experience in producing PE pipe mould. The development of PE pipe market is also bound to a higher requirement of pipe mould. Our mould has high quality 3Cr17 Mould Materail and high service.

Features:

1.Using the overall flowing path core support structure.

2.Using the removable locating devices.

3.The channel design has avoided the dead area and retention.

4.The optimized design of the flowing channel gives it a stronger impact resistance .

5.The inside and outside surface of the profile is smooth and without scratches.

6.Easy to assemble and disassemble.

7.The mould has high stability and high extrusion speed.

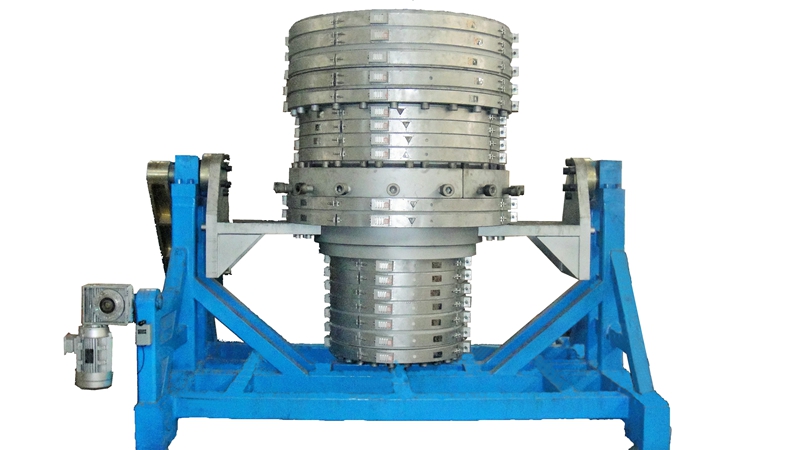

Name | Plastic Extrusion Pipe Making Mold |

Size | Various types |

Mould material | 3Cr17, 3Cr17MoNiV,or as per your request |

Mould cavity | 1 or multi-cavity |

Mould composition | Die head, aluminum heating bands, calibrators and water tank |

Feature | Selectable co-extrusion of different raw materials: PVC, PP, PE, ABS |

Selectable technology: low-foaming, high-foaming & substance co-extrusion | |

Stable discharging, high efficiency, superior quality | |

Test | Mould will be tested to get the satisfied sample before delivery |

Service | Provide complete set of production process and technology transfer service |

Lead time | 35-40 days |

Package | Wooden case for exporting, each mould will be cleaned before packaging. |